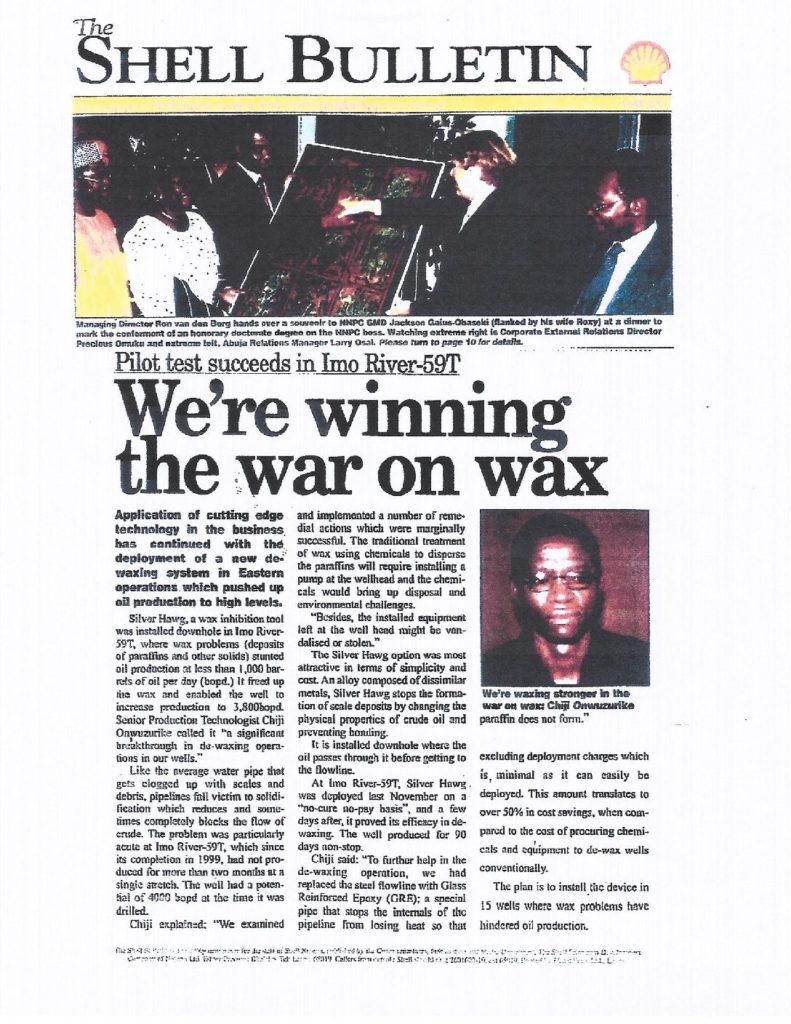

Shell Nigeria presented a land-based horizontal well 59-T producing from the D3-000C Reservoir. This well had the potential of producing over 3000 bbls/d; however, the constant buildup of paraffin restricted the continuous flow of crude oil and required downtime for cleaning and treating the well. The problems resulted in an average production of 570 bbls/d, well below the well’s potential.

The paraffin build-up was occurring at approximately 835 feet; ideally, the tool would be placed about 500 feet below the start of the wax build-up or 1,300 feet. To make matters more complicated, Shell changed the flowline and installed a glass-reinforced epoxy (GRE) pipe. Because of this type of pipe, the Pc3 System, formally known as the “Silver Hawg,” had to be installed at the next profile which was a Baker sliding sleeve located at 6,008 feet. The tool was successfully installed, and the well was brought back online increasing output from 570 bbls/d to an average of 3,155 bbls/d.

Eighteen months after the initial operation of the Pc3 System in well 59-T, a wireline was introduced to evaluate the conditions of the well and indicated that the well was mostly wax-free although a gauge cutter had some wax cutting up to 700 feet. Unfortunately, Shell Nigeria stopped operations 8 months after the report due to community problems and has stopped operating land-based wells in Nigeria.

The success of the Pc3 System in the Shell 59-T well is featured in a Full-Length Research Paper “A proactive approach for predicting and preventing wax deposition in production tubing strings: A Niger Delta experience.” Published in the Journal of Petroleum and Gas Engineering Vol. 1(2), pp. 26-36, April 2010, which is available on request.

For more information click on the images below: